Functional Cosmetics Formulation Revision: ‘Solid Form’ Introduced, Expanding Data Exemption

Whitening and wrinkle improvement solid cosmetics can be launched with just a report… Revision of test standards planned by 2025

A new turning point has opened in the functional cosmetics market, which was mainly dominated by liquid forms. With the announcement by the Ministry of Food and Drug Safety to officially include ‘solid form’ as a new functional cosmetics formulation by 2025, the way has been paved to launch products with just a report. This decision enables the industry to respond to the market with a more streamlined product review process.

Why Are Solid Form Cosmetics Gaining Attention Now?

Over the past few years, sustainable consumption, considering the environment, has rapidly spread in the cosmetics industry, increasing interest in solid form cosmetics. They contain almost no water, reducing the use of preservatives and they have relatively less burden in terms of hygienic management during distribution and storage. Furthermore, because solid products are small and lightweight, they are useful for travel or outdoor activities.

Usually made through compression or molding methods, and formed with solid oil ingredients like shea butter or wax, solid form is becoming established as a sustainable product line rather than a simple trend. It does not require previous complex filling processes or emulsification steps, thus simplifying production processes.

“Solid form maintains stability even without preservatives, aligning with more intuitive naturalism consumption patterns.”

What Changes Are Brought by the Revision of MFDS Notice?

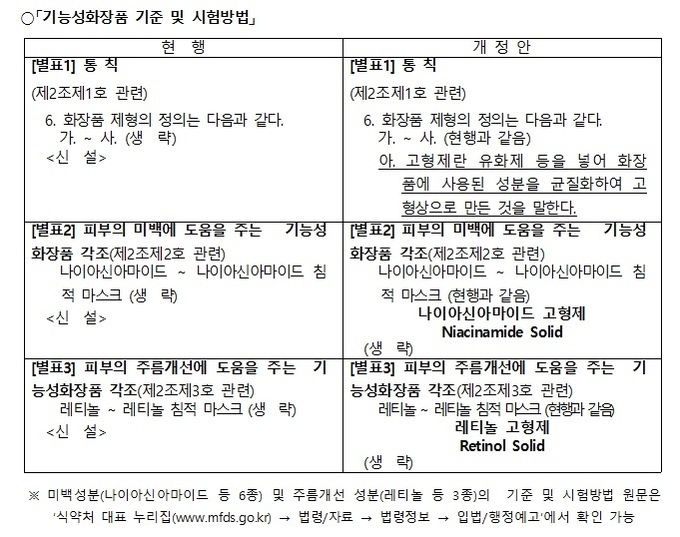

The MFDS has issued a pre-notice for the ‘Functional Cosmetics Standards and Test Methods’ revision, planning to gather industry opinions until November 26, 2025. This revision contains two key points. Firstly, a solid form will be established as one of the functional cosmetics formulations; secondly, the range of formulations exempt from data submission will include solid form.

Until now, only a few formulations like lotions, solutions, creams, and submerged mask sheets were recognized as functional cosmetics eligible for launch without data submission. However, with this revision, once solid form is officially added to this list, companies can market solid form functional products with just a report, significantly reducing resources needed for development and launch.

“When solid form is recognized as a functional formulation, it will be possible to launch various types of eco-friendly cosmetics with whitening and wrinkle improvement effects.”

Manufacturing Efficiency and Cost Reduction Benefits

Solid forms also hold attractive aspects in industrial terms. They have lower manufacturing costs compared to liquids. Their extremely low water content means they don’t require preservatives, and the production facilities and packaging containers need simple technology. The hygiene risk in filling processes is nearly nonexistent. This structure directly links to cost reduction and can particularly enhance productivity and profitability during mass production.

Transportation costs and storage space are more efficient than general liquid cosmetics. Sufficient stability is ensured even with single-box packaging or minimized packages, reducing logistics burdens. Especially in a market predominantly with online distributions, products can be reliably delivered to customers without concerns of leakage during shipment.

“It is a formulation that can satisfy consumer needs for simple yet substantial products while also meeting manufacturing efficiency.”

Solid Form Emerges as an Answer to the Eco-Friendly Trend

As consumer trends shift, ‘eco-friendliness’ has become an inevitable topic in the cosmetics industry. Solid form is evaluated as a formulation optimized for this trend. As it uses significantly less water compared to liquid products, the overall water usage in the production process is reduced, and waste is also greatly diminished.

Moreover, it can reduce dependency on plastic containers. It is easy to switch to packaging with various materials such as paper and metal, which positively contributes to enhancing ESG strategies at brand levels. In fact, many companies are considering the expansion of solid form lines alongside the zero-waste concept.

“Water use reduction and packaging simplification go beyond a mere eco-friendly concept and become a meaningful strategy in terms of brand identity.”

Will It Improve Consumer Experience? Barriers to Overcome Exist

Of course, solid form is not an all-in-one solution. Given its characteristics, it is often applied directly to the skin or used by melting, requiring a more delicate approach in designing consumer experiences. For instance, key factors in product selection could include whether it applies smoothly without irritating the skin or whether it doesn’t leave stickiness or dryness.

Moreover, solid form is not realistically suitable for all types of functional cosmetics. There are still parts where it does not respond sufficiently for formulations important for absorption like serums or products requiring quick action. Thus, detailed strategies for each product need to be designed between the limitations and possibilities of solid form.

“If not designed to blend naturally into the everyday life of consumers, commercialization could still face challenges.”

Over the past few years, the cosmetics industry has undergone significant changes centered on eco-friendliness and sustainability. is partnering in creating a sustainable future through reliable solid form functional cosmetics in line with these trends.